As a consumer have you ever wondered, How much does it cost to make a pair of jeans?

The usual retail prices varies with the region but on an average including all big brands, stores & chains, an average pair basic pair of jeans would cost $20. You may take this figure as a benchmark to understand the dynamics of this industry and what elements I aim to bring forward to you.

So how much would a minimum basic pair of jeans cost to the brands/retail stores/ chains etc. Any guesses??

$8, $10, $15.... nope

An average pair of jeans for mens would cost around $5 to $6 to the brand and in-turn it would be retailed on a minimal base price of $20 (Formula of 3: Selling price of 3 times or more than the average purchase price) and more. Brands do pay more or less as per their approved product detailing. For any supplier able to charge $10 and above to the brands is considered as premium goods manufacturer.

An average pair of jeans for mens would cost around $5 to $6 to the brand and in-turn it would be retailed on a minimal base price of $20 (Formula of 3: Selling price of 3 times or more than the average purchase price) and more. Brands do pay more or less as per their approved product detailing. For any supplier able to charge $10 and above to the brands is considered as premium goods manufacturer.

Considering $6 as a base figure to compare, which costs does the supplier have to cover in this $6. The supplier has to cover all the following costs:

- Overhead (fixed cost: includes utilities, salaries and all pre-requisite operational expenses)

- CMT (Variable Cost: Cut, Make and Trim Cost, Directly linked with the production of goods)

- Washing (The most complicated process, a wash recipe may cost from $0.50 up-to $2.00)

- Fabric (biggest element of the cost structure with price variability of $2 and above per meter)

- Material Costs (Threads, Zippers, Labels, Tags, Buttons, Rivets, Packing material, etc)

- Wastage (costs incurred through faults during the production process)

- Bank Charges (Taxes, Bank Processing Fees)

- Testing & Inspection Charges (Testing as per the EU & USA Standards)

- Transportation, Logistics/ Courier Charges (Goods Transportation (sea), samples delivery etc).

After in-curing all these costs, the suppliers then have their profit margins which in-turn fall some where between $0.10 (minimum) to $0.25 (maximum). The payment terms from the Brands are usually on credit primarily through Letter of credit (L/C) which can only be negotiated once the documents have been accepted and the goods have reached the destination. Consequently from the confirmation of an order till the time its dispatched and reached the destination and the payment process, the whole process takes on a an average of 4 months (120 days). Usually the manufacturing companies have to work through extensively, to achieve an environment of economies of scale to be able to meet the tough pricing standards set by the brands.

As a consumer/layman one might wonder that how do companies operate, survive and grow in this tough perfect competition market. Well the expenses and the requirements don't just stop here with the pricing standard. There is a long list of requirements set by the customer in terms of their code of conduct, GSP standards, BCI Standard, EU regulations, Compliance Certifications & Sustainability. The cost of compliance is never cheap, yet all standards have been given by the customer to follow as a pre requisite to start and maintain business. That is why over the last decade the barriers to entry in the textile garment industry have been very high. Strong capital costs are required with an extended long term payback period. So many new players who have keen interest in joining this Business/Industry fall short on high capital investments, pre-requisites set forth by the brands in starting business, longer credit terms, high proportion of current capital investment in stocks and material. The prevailing players who have survived in this industry have done well over the years despite of the challenges they have faced over the last decade or so.

Covid-19 hit the garments and the brands pretty bad. Any thing termed non-essential, has suffered the wrath of this pandemic virus. Lives, Businesses, Industries and Economies all have suffered drastically. When this virus broke out in China, many were unsure and relaxed that this spread would be contained in the China. But what they couldn't foresee was that this out break would travel leaps and bounds and would affect nations, countries, and millions of people. No one would have forecasted countries being lock down for a period of 2 weeks and more. No one would have accurately predicted what kind of loss both human and financial the people would have to suffer and go through. But the situation got worse. Italy amongst the European nations was the first to close, followed soon by Spain, then Germany and so on. The worst impact came when UK & USA decided to get off. But brands being off was expected. what wasn't expected was when brands started cancelling orders.

Pakistan went into lock down on 23rd March, 2020. Before we had gone in lock down, we had received emails from customers in Italy of stopping the production. We received emails from customers in UK that all present production is stopped until further notice. All future confirmed orders are cancelled. Similar was the experience from customers in Spain and other parts of Europe. Many customers extended the letter of credit periods, others started asking for discounts, while most of them went for immediate cancellation. In a very short span of time, things became worst for all garment manufacturers across the globe. I would like to mention here that the payment cycle for manufacturers may be based on a lead time (as explained earlier of an approximate 120 days) but the expenses/salaries of the workers, vendor payments every thing is made periodically as soon as they are accrued. Buyers/Brands shutting off and essentially walking way from ready shipments have left things in a turmoil. Like all global companies, financial planning for manufacturers is done in advance. Procurement of raw material is done at the time of confirmation of order booking. Not only are the manufacturers stuck with investments made in raw materials but also in the production work in progress, ready to dispatch shipments amongst other amenities. The marketing people of different manufacturing organisations have been in contact with the buyers/brands but there is no clear status.

Further breaking it down for understanding, Pakistan total employment accounts for 49 Million people. Out of 49 Million, roughly 30% or approximately 15 Million people are employed by the textile industry alone in pakistan. On a whole pakistan is the 8th largest manufacturer of textile products in Asia. The average annual per capita income in Pakistan is $1230/- to $1250/-. The minimum wage in Pakistan for un-skilled worker is $90/- Month or $1,080/- Annually. Comparing to Bangladesh who is the 2nd largest producer of textile products in the world after china. Bangladesh employs 45% of its all employment force in the textile sector. More than 4500 factories are operational there with an approximate employment force of 4.1 million people. The per capita income of Bangladesh is $2,068/- Annually and has minimum wage of $89/- Month and $1,065 annually.

Brands closure for indefinite period, impact of delayed/cancelled orders, payment cycle revisions all this will significant impact on the workforce of these 2 countries. Potentially mass unemployment is expected in the textile sector with layoffs and retrenchment going up to 60% to 70% in the coming months in the textile sector. Figuratively we are looking at 10 million people on an average who will be laid off on a whole in both countries.

The impact would have been far less, if the buyers/brands had stood up to their commitments and taken the goods/shipments which are ready or in the production cycle. it would have given an approximate 3 to 4 weeks of leverage to manufacturers to plan their payments/ production process and then gone towards retrenchment. The world soars with corona virus as we speak today. Globally every thing is on a stand still. The deepest sympathies go out to everyone who is presently suffering from this virus. Condolences to all those people and families who have lost their loved ones in fight against his virus battle. But the west and developed countries also need to understand one thing, corona may affect many, but mass un-employment would affect all. Especially the 3rd world countries where majority of the population revolves around or below the poverty line.

Textile industry has revolved around the ethical code of conduct & sustainability over the last decade or so. Where are the Ethics Today? Where is Sustainability? Every buyer/brand/store would categorise their supply chain as a business or strategic partner. Today this term seems irrelevant. Supply chain are just partners of convenience. Its seem clearly enough when brands wanted orders at a competitive price, shorter lead times, the supply chain was conveniently available. Whenever these brands would get their supply chain audited on ethical, social, healthy & safety standards: payment of wages and salaries would be deemed as critical issue. Any discrepancy on that front would immediately result in the lowest rating of Audit given to the manufacture and Brands would reserve the right to cancel all placed orders. Manufacturers/ Factories would need to submit corrective actions with evidence to the Brands and yet the impact on loosing of business would be great. Today as the textile industry stands on the verge of collapse, where are the founders of compliance today. Where are the ethics & where are the highest standards that were preached to the manufacturers as pearls of wisdom. Its unfortunate to see how most brands have acted and just put a shut eye to all of this.

It is worth mentioning here not all brands have walked out from suppliers. H&M, INDITEX, M&S, Target Stores, PVH, KIABI are amongst the few that are worth mentioning that have come forward and assure their supply chain partners that they will take all goods which are in the process of production. They are presently revising payment schedules and have assured suppliers that they will make payments for ready goods. This news is a breath of fresh air for suppliers working with these prestigious brands. The respect and appreciation of all these brands who are owning up to their commitments is enormous and well appreciated throughout the textile industries operating across the globe.

It is worth mentioning here not all brands have walked out from suppliers. H&M, INDITEX, M&S, Target Stores, PVH, KIABI are amongst the few that are worth mentioning that have come forward and assure their supply chain partners that they will take all goods which are in the process of production. They are presently revising payment schedules and have assured suppliers that they will make payments for ready goods. This news is a breath of fresh air for suppliers working with these prestigious brands. The respect and appreciation of all these brands who are owning up to their commitments is enormous and well appreciated throughout the textile industries operating across the globe.

Pakistan went into lock down on 23rd March, 2020. Before we had gone in lock down, we had received emails from customers in Italy of stopping the production. We received emails from customers in UK that all present production is stopped until further notice. All future confirmed orders are cancelled. Similar was the experience from customers in Spain and other parts of Europe. Many customers extended the letter of credit periods, others started asking for discounts, while most of them went for immediate cancellation. In a very short span of time, things became worst for all garment manufacturers across the globe. I would like to mention here that the payment cycle for manufacturers may be based on a lead time (as explained earlier of an approximate 120 days) but the expenses/salaries of the workers, vendor payments every thing is made periodically as soon as they are accrued. Buyers/Brands shutting off and essentially walking way from ready shipments have left things in a turmoil. Like all global companies, financial planning for manufacturers is done in advance. Procurement of raw material is done at the time of confirmation of order booking. Not only are the manufacturers stuck with investments made in raw materials but also in the production work in progress, ready to dispatch shipments amongst other amenities. The marketing people of different manufacturing organisations have been in contact with the buyers/brands but there is no clear status.

Further breaking it down for understanding, Pakistan total employment accounts for 49 Million people. Out of 49 Million, roughly 30% or approximately 15 Million people are employed by the textile industry alone in pakistan. On a whole pakistan is the 8th largest manufacturer of textile products in Asia. The average annual per capita income in Pakistan is $1230/- to $1250/-. The minimum wage in Pakistan for un-skilled worker is $90/- Month or $1,080/- Annually. Comparing to Bangladesh who is the 2nd largest producer of textile products in the world after china. Bangladesh employs 45% of its all employment force in the textile sector. More than 4500 factories are operational there with an approximate employment force of 4.1 million people. The per capita income of Bangladesh is $2,068/- Annually and has minimum wage of $89/- Month and $1,065 annually.

Brands closure for indefinite period, impact of delayed/cancelled orders, payment cycle revisions all this will significant impact on the workforce of these 2 countries. Potentially mass unemployment is expected in the textile sector with layoffs and retrenchment going up to 60% to 70% in the coming months in the textile sector. Figuratively we are looking at 10 million people on an average who will be laid off on a whole in both countries.

The impact would have been far less, if the buyers/brands had stood up to their commitments and taken the goods/shipments which are ready or in the production cycle. it would have given an approximate 3 to 4 weeks of leverage to manufacturers to plan their payments/ production process and then gone towards retrenchment. The world soars with corona virus as we speak today. Globally every thing is on a stand still. The deepest sympathies go out to everyone who is presently suffering from this virus. Condolences to all those people and families who have lost their loved ones in fight against his virus battle. But the west and developed countries also need to understand one thing, corona may affect many, but mass un-employment would affect all. Especially the 3rd world countries where majority of the population revolves around or below the poverty line.

Textile industry has revolved around the ethical code of conduct & sustainability over the last decade or so. Where are the Ethics Today? Where is Sustainability? Every buyer/brand/store would categorise their supply chain as a business or strategic partner. Today this term seems irrelevant. Supply chain are just partners of convenience. Its seem clearly enough when brands wanted orders at a competitive price, shorter lead times, the supply chain was conveniently available. Whenever these brands would get their supply chain audited on ethical, social, healthy & safety standards: payment of wages and salaries would be deemed as critical issue. Any discrepancy on that front would immediately result in the lowest rating of Audit given to the manufacture and Brands would reserve the right to cancel all placed orders. Manufacturers/ Factories would need to submit corrective actions with evidence to the Brands and yet the impact on loosing of business would be great. Today as the textile industry stands on the verge of collapse, where are the founders of compliance today. Where are the ethics & where are the highest standards that were preached to the manufacturers as pearls of wisdom. Its unfortunate to see how most brands have acted and just put a shut eye to all of this.

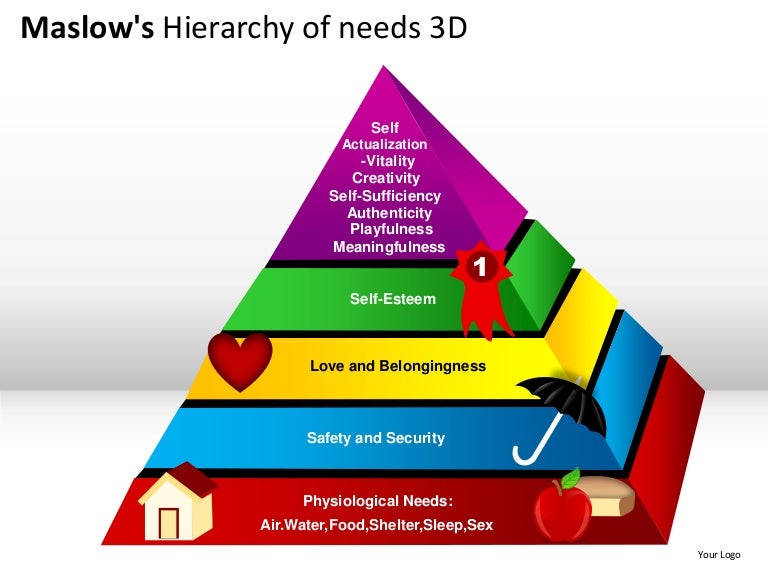

One might wonder what is the actual reality? The Compliance Standards/Code of conduct Preached for over a decade or this

It is worth mentioning here not all brands have walked out from suppliers. H&M, INDITEX, M&S, Target Stores, PVH, KIABI are amongst the few that are worth mentioning that have come forward and assure their supply chain partners that they will take all goods which are in the process of production. They are presently revising payment schedules and have assured suppliers that they will make payments for ready goods. This news is a breath of fresh air for suppliers working with these prestigious brands. The respect and appreciation of all these brands who are owning up to their commitments is enormous and well appreciated throughout the textile industries operating across the globe.

It is worth mentioning here not all brands have walked out from suppliers. H&M, INDITEX, M&S, Target Stores, PVH, KIABI are amongst the few that are worth mentioning that have come forward and assure their supply chain partners that they will take all goods which are in the process of production. They are presently revising payment schedules and have assured suppliers that they will make payments for ready goods. This news is a breath of fresh air for suppliers working with these prestigious brands. The respect and appreciation of all these brands who are owning up to their commitments is enormous and well appreciated throughout the textile industries operating across the globe.

But what about the rest. will they come out of their shells. Will they come to aid of their strategically convenient supply chain or would they let them suffer? In a news article yesterday it was announced Primark & Matalan amongst retailers allegedly cancelling £2.4 Billion orders (Guardian: https://www.theguardian.com/global-development/2020/apr/02/fashion-brands-cancellations-of-24bn-orders-catastrophic-for-bangladesh). It didn't matter if the manufacturer had worked with a Brand for 1 year or Many years. The decision has been same in most cases by most brands to simply cancel the orders, irrespective of what relationship they have shared over the years with the manufacturer. This decision in literal terms has been cold and swift.

The biggest catastrophe of the last decade in the Textile Sector has been the 2013 Rana Plaza Garment factory collapse in Dhaka-Bangladesh. More than 1100 people died that day due to a fire which broke-out in the factory and the building collapsed. It was a tragedy of great volume. One of the most renowned brands were being produced at that facility and all of them came forward in aid of the affected and their families. The owner of the facility was send to prison over charges of murder, heavy loss of life and corruption. Manufacturers have evolved since then primarily due to the impressive mega campaign run by the brands and other social organisations to improve the working facility standards. Countless seminars, meetings, audits have been conducted to assure that such an incident is not repeated. we hope and pray for the same. The Rana plaza incident affected 1100 families. Mass unemployment is going to affect million of lives and families. Why are the social organisations/ ethical trading bodies/ brands all quiet about this. I have also written about the suppliers role as well and the possible negative out backs expected. you may read the article : "COVID-19, Pandemic & Textile Industry of Pakistan" (https://think--re-think.blogspot.com/2020/03/covid-19-pandemic-textile-industry-of.html ). The question remains in balance, waited to be answered. The World is Watching.

One thing will come out of this. In time the clothing and textile industry will revive and brands will reopen. Clothing & Textiles is a very close second to the essentials. But this time around the tables will turn. Suppliers that survive will choose only to work with brands & stores that have stood up with them and their commitments in this desperate time of need. In time it seems the paradigm will shift. The business structures will evolve and new strategic partnerships will be made with brands not just based on order quantities but on commitments honoured. Brands that left the supply chain high & dry in this time would need to put in extra efforts to win back the confidence of suppliers.

The world on a whole will change. The damage too soon to forecast, but yes its going to be massive. The economies will change, the working models will change, life styles will change. Lets hope and pray that this pandemic comes to an end and the world as whole is able to counter-off this Covid-19 threat & its after math.

Stay Safe, Stay Inside

Muhammad

5th April, 2020

Being a Native of third world, I condemn this Cruelty. All the Suppliers should be helped by Brands in this Misery of poverty which can be occurred in third world States if still this Situation Persists . I appreciate Mr. Muhammad who wrote this Dichotomy which will help suppliers in future to Redevelop Business on the bases of Commitments were honored or not....

ReplyDelete